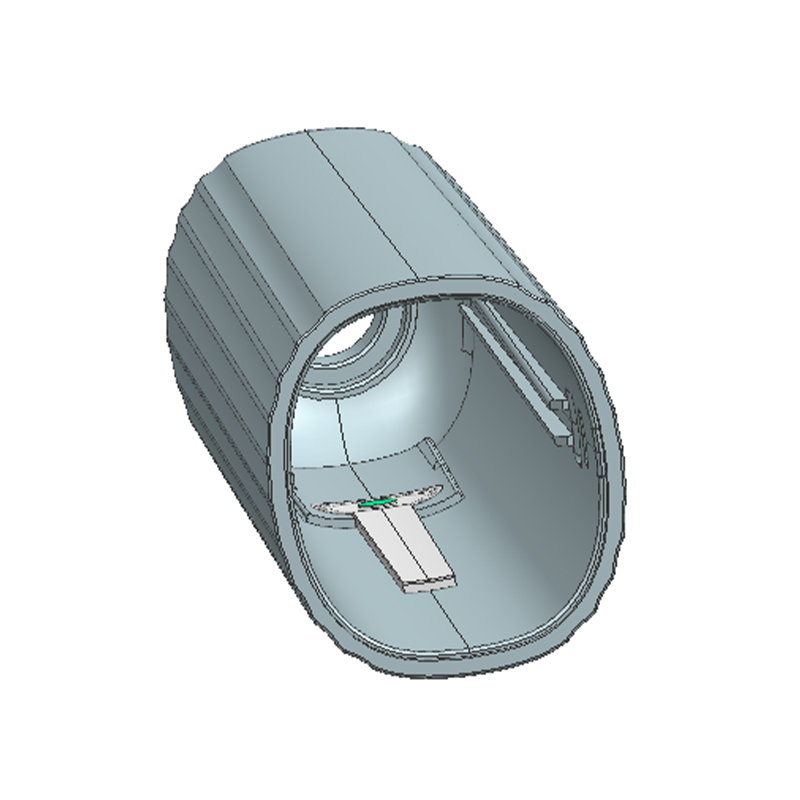

Against this backdrop, plastic mold manufacturing technology using integrated molding processes is becoming a key tool for improving the structural strength of balcony energy storage shells.

- +86-13691916748

- jto-zl-gc001@jto-zl.com

- Building 2, Wan'an Industrial Park, Shayi Community, Shajing Street, Bao'an District, Shenzhen